For more than a decade at the start of the 21st century, the Government drove efforts to explore the validity of solar renewables; first solar photovoltaics for generation of electricity, and later solar thermal as a means of capturing solar energy onsite for water heating.

Purchasing flat plate or evacuated tube systems proved cost-effective, and the technology enjoyed a hey-day with many school buildings employing one or both options.

Nearly 15 years on, many of those systems now sit unusable on the roofs of those buildings. The causes are varied; poor initial installation issues and particularly a lack of servicing and maintenance ultimately lead many systems to overheat and fail, even sealed systems. Manufacturer support for evacuated tube systems also waned as key suppliers moved away from the technology. Some sites suffered from costly vandalism. For many schools, the costs of protecting an installation or repairing it were too high and they were simply switched off and written off as a loss.

Solar technology did not die though. Properly installed and serviced solar thermal systems prove to have a long operational lifespan with low maintenance demands, especially flat plate collector systems. Those with proven drainback technology employing gravity flow to preserve operational qualities of the solar fluid required to transfer solar energy as heat to the hot water application are notably robust. A well-designed and balanced hot water system deploying solar thermal as a preheat can offset a minimum of 30% of the annual energy demands for hot water in the UK. For some regions, this percentage is much higher and in the summer months, solar can meet all a system’s heating demands, especially in the case of buildings with lower daily hot water demands such as offices and classrooms.

The drive for net zero has also helped reinvigorate interest as education is challenged to transition from gas to electric water heating. As grid electricity continues to be substantially more expensive than gas (by a factor of 5.5 at the close of 2023) the energy bill shock from transition for many has meant technology that can offset electrical energy usage is becoming more attractive. The return on investment (ROI) for solar thermal is once again powerful, with systems able to pay back capital investment in under 10 years.

The New Rooftop Battleground

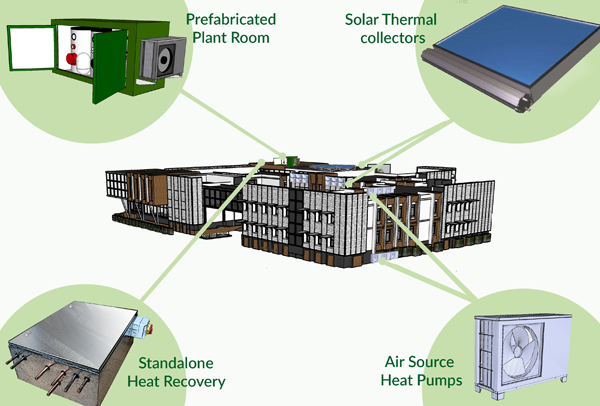

Chillers, heat pumps and solar systems are all vying for valuable rooftop space as schools look to reduce carbon emissions and embrace high-efficiency heating and cooling. We would always advocate splitting solar water heating (solar thermal) from solar space heating (PV) to gain the greatest efficiencies. Specifications will often aim to deploy solar photovoltaics (PV) to supply electricity for space heating and hot water. When retrofitting gas-based hot water systems this is a less efficient route since PV will always offset grid electricity at 136g/KWh, equivalent to 18 kg of CO2/m²/annum. Compare this to solar thermal which offsets gas emissions at 233g/kWh, or 148 kg of CO2/m²/annum. This makes solar thermal eight times more effective per m² than PV when addressing carbon emissions from water heating, translating to a smaller panel area for solar thermal on the rooftop.

Resurrecting Solar Thermal

With new high-efficiency, robust flat plate collectors and protective drainback, cylinders and controls to integrate solar thermal with electric top-up there is a real opportunity to resurrect systems which have fallen into disrepair. Most refurbishments where overheating has been the cause of shutdown will require new collector panels and pipework which fortunately is a relatively straightforward replacement as the re-installation process will have minimal impact on extant plant room appliances. This allows for upgrading existing gas water heating, saving energy, and reducing emissions from the existing system.

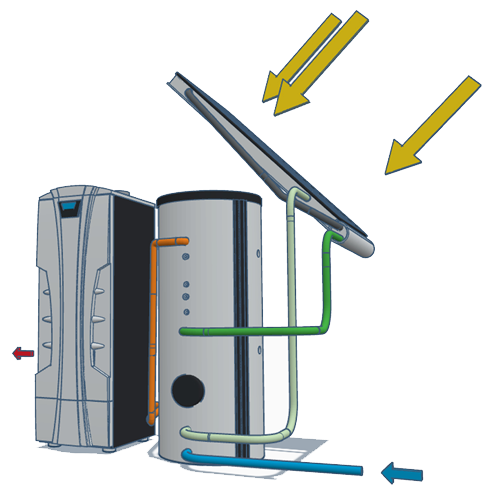

Alternatively, Adveco can support the transition to full electric water heating with solar thermal through bespoke system design and product supply. For smaller systems and schools with lower capacity demands, Adveco FUSION offers a pre-defined low-carbon system that is compact, easy to install, resilient and cost-effective. For organisations which are considering but not ready to commit to a heat pump-based system, FUSION T is available now with an option that delivers a twin-coil stainless steel tank and mounted ARDENT electric boiler and controls without the heat pump preheat. This iteration allows for solar thermal to be introduced into the lower coil as the system preheat with a small amendment to the controls to optimise top-up heating from the boiler as the pre-heat fluctuates across the year.

With FUSION now supporting capacities up to 750 litres with 24 kW heat output, it is suitable for solar systems designed for small to medium-sized buildings. While most solar thermal systems would be designed to split the preheater and after heater, this single-cylinder FUSION scenario avoids the typical requirements of a 50/50 capacity split between preheat and top-up. Adveco’s smart controls allow the system to ‘cheat’ in favour of the solar thermal delivering a 600-litre solar capacity in a 750-litre tank for an extremely compact option for an all-electric low-carbon emission solar water heating system with a minimal rooftop or façade footprint.