Do your homework before replacing schools’ gas-fired water heating

By Bill Sinclair, technical director, Adveco.

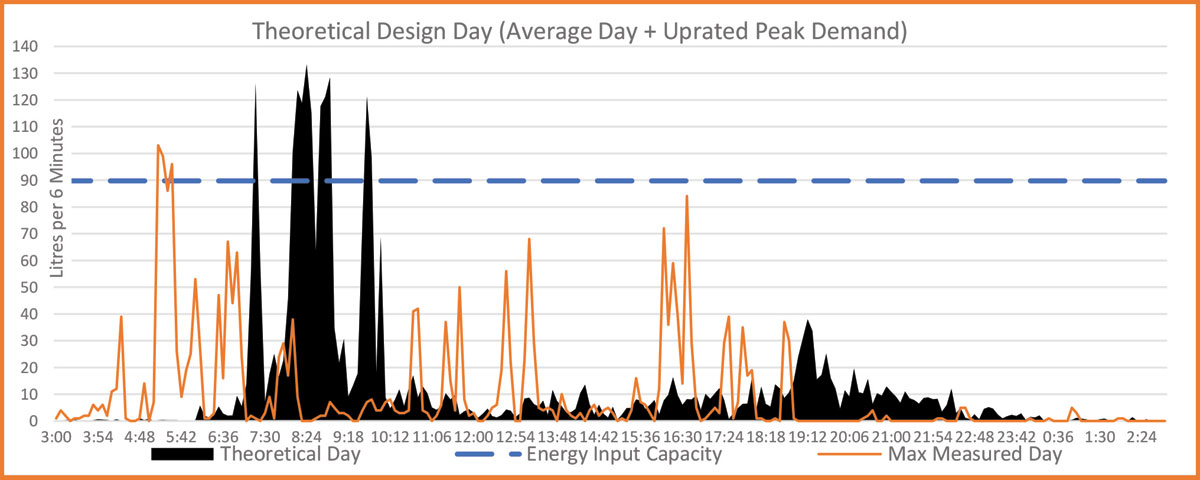

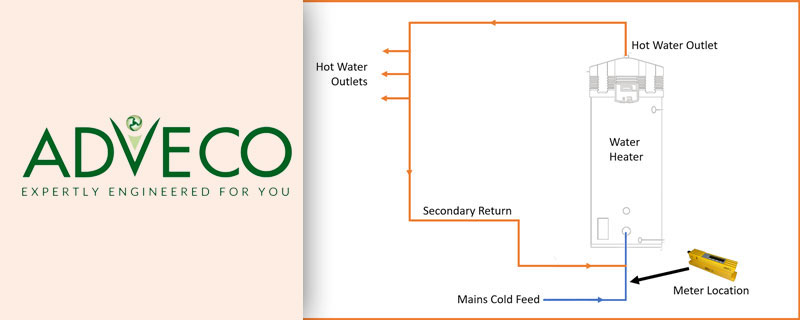

The most consistent issue we see in school hot water systems is oversizing, whether through a lack of understanding of application design or concerns over providing suitable backup to ensure system continuity. The result of oversizing is however always the same, unnecessary capital costs for system supply, installation and ongoing excess operational costs associated with higher energy demands and therefore greater carbon emissions. As schools plan to adopt greener building operations, replacing old gas-fired systems with like-for-like electric is another guaranteed way to gain an oversized system, but can also lead to undersizing if storage is not large enough to account for low, slow heating associated with heat pump based electric systems. Getting that balance right is critical as per kW price of electricity remains much higher than that of gas. Plus, if not optimised, the system will generate excess capital costs in terms of size and number of water heating appliances and complexity of installation. That in turn can also become more time-consuming and disruptive, a cause for concern if refurbishment work is scheduled into the narrow window afforded by the school holidays. More importantly, if the new electric system is oversized the required amperage could exceed a building’s available electrical supply. Bringing new supply in means excavating, possibly as far as the substation, which will see cost soar, or even stall the project. This can best be avoided by collecting live onsite data. A valuable, non-invasive, and low-cost exercise, it should be undertaken to assess actual usage, including time and duration of peak demands which is critical for correct sizing. When assessing a school’s domestic hot water (DHW) usage, it is important to also establish basic information on energy sources, be they gas or electric, planned use of renewables such as heat pumps or solar thermal and the level of system redundancy and backup. This helps steer the design of the replacement system.

This approach has already been applied to several public sector sites in the UK where there is a strong impetus from the government for properties to be rapidly decarbonised in line with net zero strategies. Data collected by Adveco has enabled our application design team to provide recommended alternatives that avoid common issues arising from oversizing.

One recently assessed dormitory site was operating two 50kW output gas-fired water heaters and a pair of 140 kW boilers. Replacement plans included making use of two additional electric boilers with an air source heat pump (ASHP) to heat the building. Live metering indicated that the property exhibited an average daily usage of 1793 litres with a maximum daily recorded usage of 2407 litres, averaging out to 2003 litres. The single peak, spread between 7 am and 10 am, was contrary to the perceived dual morning and evening peak. With a long, low single morning peak the theoretical design day hot water consumption was established at 2789 litres.

On this basis, with a 20% uprate added to ensure extraordinary peak demands would be accommodated in the system design, requirements can be met by a 24kW electric system with 250-litre storage. This assumes 40°C preheat feed from the air source heat pump, 63°C storage and supply at 60°C. The recommendation was for a 500L twin coil cylinder, with the bottom half preheated by the ASHP and the top half heated by a 24kW electric boiler, such as Adveco’s ARDENT. The storage cylinder is derated by 50% as only the top half is guaranteed to store water at a usable 60°C. A smaller boiler could be specified and would cope as well, but without the ASHP preheat the full 24kW would be required ramping up operational costs.

The new system will have an estimated annual consumption of 616,564 litres. With an estimated 16,544 kWh thermal energy demand for the year, carbon emissions fall from 8340 kg/annum for the gas-fired system to 3250kg/annum for the new electric heated system. A carbon reduction of 5090 kg/annum. However, annual electric running costs, despite a 25-35% offset in energy from the heat pump, would be an estimated £2813, compared to lower-priced gas costs of £689.

Replacing gas-fired water heating with an electric system still has several cost implications. Correct sizing with metered data can reduce the costs of purchasing and installing new hardware, potentially saving tens of thousands of pounds depending on the scale and complexity of the DHW application. Excavation works to bring in increased electric supply though can quickly raise project costs to anything as high as £500,000 if in a city location! So optimising designs to avoid this is critical. Operational costs do however climb and will continue to do so while grid electric prices remain much higher than those of gas grid supplies. The application of renewables including heat pumps and solar thermal can reduce, but not completely offset those direct electric costs.

The advantage is clearly defined in the reduction of carbon emissions, and, as work continues to decarbonise the electricity grid, the emission reduction figures supplied in the new system design should improve considerably, adding further environmental value to the system over the course of its operational lifespan. Decarbonisation of hot water still comes with implicit operational costs. Metering helps to clarify this and put a real number on the ledger that can be factored into a school’s decarbonisation strategy.

CLICK HERE TO VISIT THE ADVECO WEBSITE

Leave a Reply

Want to join the discussion?Feel free to contribute!