Alex McDonald, indoor climate specialist at Zehnder Group UK, discusses how air quality and indoor climate can impact the learning environment and student success.

A poor indoor climate, and specifically bad indoor air quality (IAQ) has a demonstrably negative impact on students’ health, concentration, and overall learning experience, often leaving them feeling lethargic and struggling to focus.

Studies have shown a clear link between high CO2 levels and decreased cognitive function, especially in the afternoons, leading to drowsiness, headaches, and difficulty focusing. In the bustling environment of a school, effective ventilation is not just a matter of comfort, it’s essential for the academic performance and health of the children.

In many cases, inadequate ventilation can exacerbate asthma, allergies and – as emphasised by the pandemic – increase the risk of airborne virus transmission, further hindering student and teacher well-being.

Achieving an optimal indoor climate, with a focus on better air quality in educational settings however, presents unique challenges. These range from varying environmental factors, such as security and pollution, to the need for well-maintained ventilation systems across different areas, including classrooms, sports halls, food technology kitchens, and more. All have different objectives and need to be modelled to achieve optimum performance across the school setting.

Building Bulletin 101 (BB101) sets out regulations and guidance on ventilation, thermal comfort and indoor air quality for school buildings. It provides guidelines on minimum performance standards for schools but hitting the minimum shouldn’t be deemed as best practice.

Ventilation strategies in schools

Within school ventilation considerations, there are three main strategies deployed – Natural ventilation by opening windows, Hybrid ventilation using a mix of mechanical ventilation and natural ventilation, and finally Full Mechanical ventilation.

While acknowledging natural and hybrid ventilation systems, BB101 guidelines were drafted in a time with less stringent energy efficiency standards and a lesser focus on consistent indoor air quality.

Natural ventilation may appear to be a simple and cost-effective solution, but it has significant drawbacks. In winter, opening windows can lead to discomfort from cold draughts causing distraction and potential health implications for occupants inside. Rapid heat loss is also an issue, negating the efficiency of heating systems and costing the school precious pounds. Then in warmer months, opening windows for fresh air can lead to pollen and allergens infiltrating classrooms as well as excess heat.

Additionally, natural ventilation is impractical in areas with high noise pollution or poor outdoor air quality especially in urban areas or near busy roads, therefore failing to meet BB101 requirements for air quality and BB93 limits on noise pollution in classrooms.

These methods are also heavily dependent on weather conditions, including wind direction; if the wind is unfavourable it won’t deliver the necessary air movement within a room to provide optimal climate.

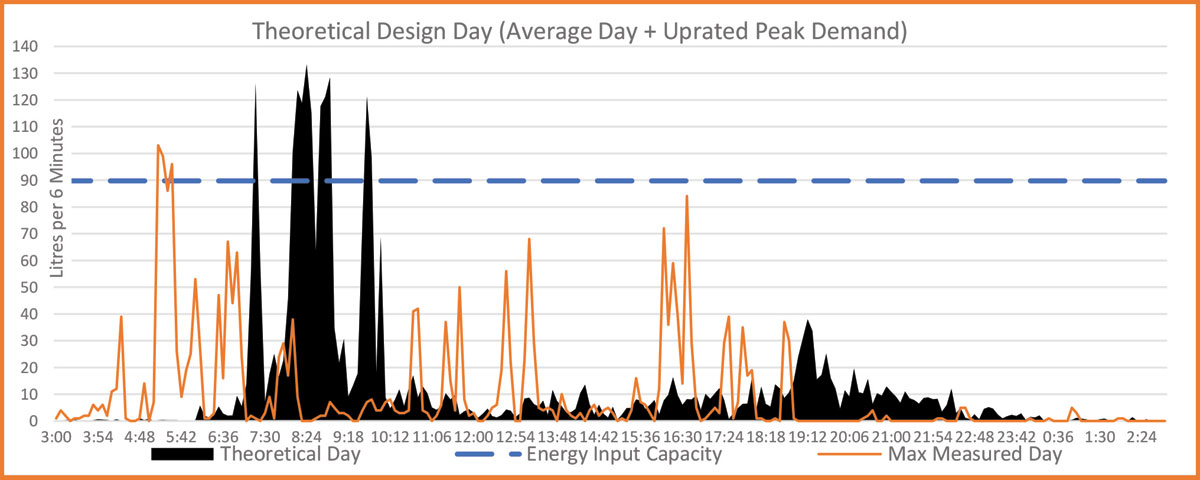

Hybrid systems, which combine natural and mechanical ventilation methods, attempt to bridge this gap but can be unreliable due to human error. These systems often rely on teachers manually opening windows, an easily forgotten task. Likewise, the inconsistent monitoring of pollutant levels can occur as teachers prioritise their lessons, often leading to dangerous CO2 spikes. Hybrid systems also struggle to maintain a consistent airflow due to the load they can produce, especially in larger classrooms with fluctuating occupancy.

For the best IAQ in schools, while still ensuring sustainability and energy efficiency, hybrid methods often fall short.

The move to mechanical

Mechanical ventilation with heat recovery (MVHR), however, removes the guesswork and gives full control over the building’s climate. An MVHR system offers a comprehensive and sustainable air quality solution with several key advantages over alternative solutions, including consistent airflow, automatic CO2 level monitoring and adjustment, that all leads to improved occupant concentration. These benefits collectively lead to reduced absenteeism from student illnesses caused by airborne viruses.

The advanced heat recovery capabilities minimise energy and heat waste, ensuring efficient operation year-round. Precise air control with CO2 monitoring guarantees consistently improved air quality, regardless of external factors or occupant behaviour.

Mechanical ventilation systems come in two types, centralised and decentralised.

For smaller projects, decentralised ventilation units provide an ideal solution. Each unit operates independently, serving individual classrooms or spaces, ensuring optimal air quality with minimal disruption. Should a unit require maintenance or encounter issues, it affects only the corresponding room, mitigating downtime and inconvenience – this makes them well-suited for retrofitting older buildings or adding ventilation to new areas, without the need for extensive modifications.

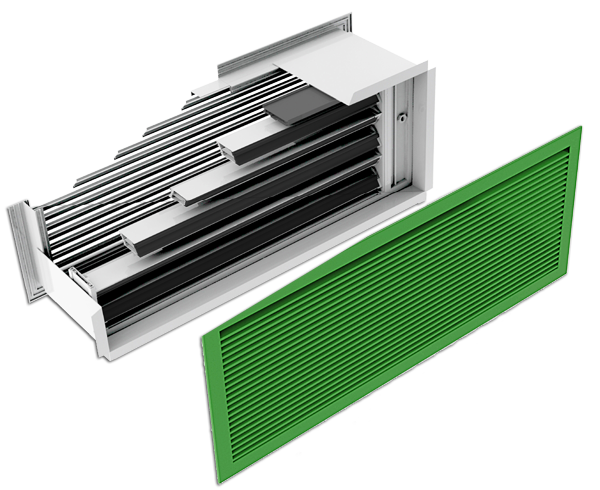

Zehnder’s decentralised ventilation solution, the Zehnder Eversky®, is designed for educational settings. With highly efficient heat recovery capturing up to 90% of exhaust heat, it’s adaptable to room-specific needs, integrating seamlessly while operating quietly. This ensures a comfortable climate while meeting air quality standards.

In contrast, larger-scale projects benefit from centralised ventilation systems – offering centralised control and distribution of air through a connected air system network throughout the entire building. By connecting all supply and extract across a school, these systems ensure uniform air quality and temperature regulation, optimising energy efficiency and reducing operational costs.

This solution is particularly advantageous for new construction projects, where they can be seamlessly integrated into the building’s design.

Zehnder’s NeoTime and Carma commercial MVHR units are designed for easy plug-and-play installation. The control panel on the unit makes installation, configuration, and operation simple. These units can be installed both indoors and outdoors, with a factory-fitted weather protection roof. They ensure optimal air quality with high-quality filters and operate quietly thanks to double-walled, insulated panels with high-density thermal insulation.

The best indoor climate

Heat recovery through an MVHR ventilation system helps to retain the heat from the extracted air but general heating and cooling for schools still needs to be considered to create an overall comfortable climate all year round.

Traditional radiators are an excellent solution for standalone projects, perfectly suited for academic buildings and schools, the Zehnder Nova Neo radiator delivers comfort and heat faster than conventional radiators through its built-in fans offering short response times, integrated dust filters and heat pump compatibility the Nova Neo helps to ensure a clean and healthy environment. They are ideal for those not seeking integration into a wider heating and cooling system.

For those seeking an alternative or complementary option, radiant panels are a fantastic choice. Installed discreetly on the ceiling, they provide efficient radiant heating and cooling for any space, from classrooms to gym halls.

Radiant panels warm objects and surfaces directly, ensuring even heating and great energy efficiency. Their slim design and ceiling placement save valuable room space, and they do not pose a burn risk, making them safe for environments with children. Additionally, in the summer, these panels can help cool the room by circulating cooled water through the system.

Zehnder’s Alumline and ZFP radiant ceiling panels respond quickly to temperature changes, offering an energy-efficient solution using up to 40% less energy than traditional heating methods, while providing architectural flexibility. These panels integrate seamlessly into all types of lay-in ceilings, especially traditional grid ceilings common in schools. They feature a high-quality powder coating finish and a discreet design, ensuring long service life. Installation is straightforward, as they are lightweight and come ready to install with simple hydraulic connections.

For those embarking on new projects this summer break, such as school refurbishments, extensions, or new constructions, these solutions provide practical, energy-efficient and adaptable options. They enable a comfortable and conducive learning environment, while prioritising the health of both students and teachers.

www.zehnder.co.uk