Megan Bennett, Product Marketing Manager at Nuaire, discusses the importance of improving air quality for schools, and how this can be achieved.

Schools should be a safe place to learn, yet 86% of new schools in England are in areas breaching World Health Organization air pollution limits; that’s 147 schools. Sadly, there is no legal requirement for air pollution to be considered in planning for new schools despite children spending on an average 35 hours a week at school for half the year.

How dangerous is air pollution for children?

In the most recent annual air quality assessment, the UK was non-compliant with the annual mean concentration limit value for NOx at a number of roadside locations in urban areas. It is estimated that 65% of the NOx concentrations at the roadside originate as NOx emissions from road transport.

Short-term exposure to concentrations of NOx can cause inflammation of the airways and increase susceptibility to respiratory infections and to allergens. Children are particularly vulnerable because their bodies, organs, and immune systems are still developing. Furthermore, children tend to spend more time outside – including travelling to and from school – so have greater exposure to polluted air.

Over the years we have come to better understand the harm brought about by exposure to external air pollution, even in small amounts. But indoor air quality is very much understudied compared to outdoor air pollution, despite the fact that it impacts pupils’ health and concentration, affecting attendance and attainment.

What can be done to improve air quality in and around schools?

Externally, the focus is on encouraging people away from their cars for short journeys and campaigning for wider access to reliable, affordable and efficient public transport The expansion of Low Emission Zones (LEZs) in urban areas is also being put forward as, despite controversy, these have been proven to reduce air pollution. In Greater London, it has been estimated that this has contributed to a 4.5% reduction in long-term health problems and an 8% decrease in respiratory issues.

But what about indoor air quality? Reducing external air pollution will have a positive impact on internal air quality, but it’s not the entire story.

Education buildings can be some of the most diverse, with most of them having classrooms, kitchens, canteens, halls, gymnasiums and even swimming pools. Indoor air quality varies tremendously not only between schools, but also within them. Effective ventilation solutions must be deployed within schools to provide good IAQ that is conducive to learning.

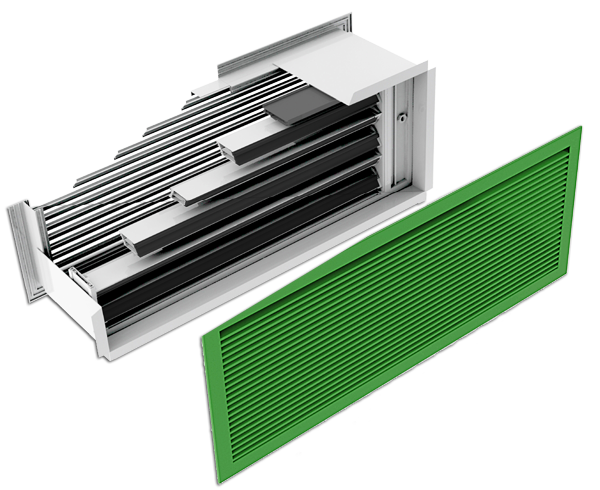

When it comes to classrooms, systems that are powerful enough able to ventilate multiple rooms and that come with a filter to remove incoming pollutants, such as the Nuaire XBOXER XBC range, are ideal.

For sports halls, the biggest challenge is CO2 and odours which must be removed. Air Handling Units are perfect for these environments as they are able to provide a high volume of air movement and do so with high efficiency. To not waste energy through running the unit when the space is not in use, it is good practice to use occupancy sensors and pollutant sensors (such as CO2 sensors) which control when units are active. This will prevent them running when ventilation is not required.

If the school is lucky has an indoor swimming pool, then a ventilation system that can cope with high levels of humidity and corrosive chlorine needs to be specified. Nuaire’s Boxer Bespoke range of AHUs can be coated for such applications.

Toilets and WCs in schools are high use areas which can fill with indoor air pollutants and odours very quickly if not ventilated correctly. Twin fans technology is standard practice for areas such as toilets. Duty share of the two fans within the unit mean that the fan continues to work in the event of one fan failing.

In school kitchens, a bifurcated fan, such as Nuaire’s Squif range, with the motor out of the airstream is a good solution, as it means that pollutants such as grease do not clog up the motor – something that can result in fan failure over time.

Addressing both external air pollution and indoor air quality is vital if we are to provide our children with a safe, comfortable place to learn. No child should have to breath dangerous or stale air just to get an education.

For more information go to www.nuaire.co.uk/commercial/education