Whether it’s a complete new-build, extension or smaller-scale refurbishment project, every investment in school buildings is under pressure to bring the best return possible. Now, some of the more enlightened manufacturers in the construction industry are focusing on producing ‘value engineered’ products specifically for the Education sector – one of which is Kawneer.

Kawneer originated in the United States over 100 years ago. Its aluminium craftsmanship can still be seen in many landmark buildings across the world including New York’s Flat Iron building and the Statue of Liberty, and over the last 50 years in the UK the company has become renowned as a leading supplier of engineered glazing such as curtain walls, windows, commercial entrance doors and framing systems.

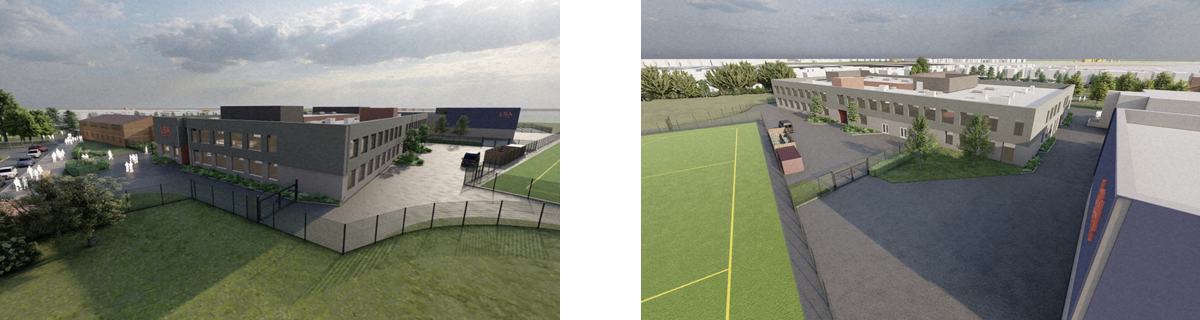

Combining those years of experience, expertise and innovation with aluminium’s flexibility and recyclability has made Kawneer’s building systems the solution of choice for many projects, particularly in the Education sector where they’re renowned for their work on construction projects from Duns Primary School in Scotland and the Smythe Library at Tonbridge School in Kent to Imperial College London and the Hauser Forum at Cambridge University.

This enviable track record of success has led to the company creating and introducing new products specifically for Education projects, the latest of which is the Kawneer AA®720 SL casement window.

Designed for learning

The AA®720 SL has been designed to bring the same level of Kawneer quality and the benefits they bring to larger construction projects to smaller and refurbishment schemes, making it an ideal choice for virtually every Education project.

A slimline (hence ‘SL’) aluminium casement window, the AA®720 SL is a high performance open-out design with ultra-slim 62mm sightlines which maximise the glazing vision area and gives a modern aesthetic look, allowing more light into the classroom while providing optimum weather and thermal performance, PAS 24 enhanced security and easy maintenance. Available with two vent style options, it’s a cost-effective and robust solution that meets or exceeds the demands of Education sector projects – as well as helping them stay on-budget.

A range of products for schools

Although only recently introduced, the AA®720 SL is just one of a wide range of matching value-engineered products specifically suited to the Education sector. These include curtain wall and framing systems, sliding patio doors, vertical sliding windows and Louvreshield ventilation, but one of the most popular choices alongside the AA®720 SL is Kawneer’s AA®190 TB all-purpose communal entrance door.

Designed for use in high traffic areas, it offers not only exceptional thermal performance and enhanced security, it’s incredibly robust – its welded corner construction, each corner having four separate weld points with a ‘lifetime guarantee’, makes it the strongest aluminium door construction available.

It also features a finger guard pivot stile as standard, safeguarding against injury to children’s fingers that might be accidentally caught between the hinge stile and frame – and making it ideal for use in schools.

A class act in sustainability

A class act in sustainability

Environmental concerns are becoming increasingly important in construction, and even more so in the Education sector. While the AA®720 SL casement window, like many Kawneer products, carries a BRE Green Guide A rating to help any project meet BREEAM standards as part of an integrated, whole building approach, Kawneer themselves are totally dedicated to sustainability.

The company uses many ways to reduce its environmental footprint, and sets new industry standards for sustainability. For example, their aluminium extrusions have a life expectancy of 50 years – far higher than other construction materials – and use a minimum of 80% recycled aluminium content. Production waste is recycled back to the smelter, and with extrusion, paint and thermal break rolling under one roof, production miles are minimised; and since 2015 they have also reduced power consumption by 24% and gas consumption by 11%, with water usage cut by 80% since 2010 and landfill waste by 75% since 2013.

Adding value in other ways

Value engineering is defined as ‘optimise without compromise’. With Kawneer, it manifests itself not just in their products, but in everything else they provide – which, combined with a thorough understanding of the need to work within tight Education budgets, can prove invaluable on any project.

They offer detailed design support right from the early stage of a project for example, with design advice to ensure their systems meet your technical and cost brief and an Architectural Adviser team on-hand to help to deliver a value-engineered solution without compromising on the quality of the system. If you need a bespoke solution their in-house facades team can provide one that fully meets specific project design criteria such as bespoke fins or brise soleil.

With all Kawneer materials manufactured in the UK, they can guarantee supply and short lead times – and hold fixed prices for the duration of a project – and they have a fully-trained network of installers to maintain the highest possible standards. On large, complex projects they also carry out regular inspections and provide a report detailing any areas that need improvement, while Kawneer products carry a unique range of guarantees from a 30-year paint warranty to the 10-year system warranty.

All of which means with Kawneer, you can always be sure you’re getting the best value possible for your Education project.

New brochure now available

To find out more about Kawneer’s long history and outstanding track record in the Education sector, together with details of all their aluminium glazing products specific to schools, their new brochure will prove invaluable. It’s available by emailing Kawneer at kawneerast@arconic.com or by visiting www.kawneer.co.uk, where it’s available as a downloadable flip-book.

The specification of the

The specification of the

A class act in sustainability

A class act in sustainability