Hassan Sherbaz, Solutions Architect at Connexin, explains how high CO2 levels can lead to disruption within schools and how smart monitoring solutions can help them make informed decisions about ventilation across their buildings to protect students.

The Department of Education recently made a major announcement that will help enhance schools’ and pupils’ safety. Within the next term, the Government will make 300,000 carbon dioxide (CO2) monitoring solutions, roughly one device for every two classrooms, available to the education sector to improve ventilation and reduce the risk of COVID-19 outbreaks.

This policy will be welcomed by many and whilst being an ambitious undertaking, it is a necessary one that will ensure schools’ premises with zones of poor ventilation are identified and the appropriate improvements are applied.

Due to the pandemic, ventilation has become an important topic within education. However, whilst COVID-19 has accelerated the focus on ventilation, it is not a new problem for schools. Research has found that poor airflow can lead to a number of problems within educational buildings, including causing drowsiness and headaches, reducing productivity, increasing the rates of absences and inflicting building damage.

Whilst ventilation has been well managed in the summer months by keeping windows and doors always open, winter is coming and schools need to find the right balance between ensuring temperature and humidity conditions are acceptable and comfortable for students. This is where CO2 monitors will have a key role to play.

The question for schools now is how can they effectively use CO2 monitors to help them improve ventilation and what solutions should they be looking to adopt?

Firstly, by monitoring CO2 levels throughout the day, schools can identify which areas require the windows and doors to be opened ahead of their unhealthy peaks, whilst still maintaining comfortable temperature and humidity. The preferred level of CO2 is currently 1000 parts per million (ppm), with an acceptable baseline of up to 1500ppm, and by ensuring classrooms remain within these levels, will guarantee there is sufficient ventilation to limit the spread of COVID-19 so that students have access to cleaner air.

However, installing and managing multiple monitors across different rooms will be a costly and time-consuming process that may disrupt pupils’ lessons. If schools want to find an effective way of implementing CO2 monitors, they need to be looking at smart technologies that are agile, mobile and provide them with vital data.

For example, by using battery powered CO2 solutions that run using a low-powered network, schools can save money by reducing the amount of monitors they need to install as these can be moved about to different rooms. Once a particular schedule for opening windows is established for certain zones, these devices can be placed in other at-risk areas, allowing schools to gain a full insight into their whole building without needing to monitor multiple, fixed devices. By monitoring CO2 levels throughout the day in this way, they can identify areas which require the windows and doors to be opened ahead of their unhealthy peaks, whilst still maintaining comfortable temperature and humidity.

At the same time, by using smart monitors, schools also have the added benefit of being able to gather and utilise data that can help them make long-term improvements to their infrastructure. These devices are constantly collecting information on the CO2 levels of the rooms they operate in, which can help facility managers identify at-risk areas to know whether a regular schedule of opening and closing windows will be sufficient to meet the required standards. If these at-risk areas can’t be managed safely, a business case can be built to retrofit or upgrade the ventilators and solutions can be implemented in specific areas, rather than unnecessary changes being made throughout the whole school, which again can prove costly and time-consuming.

The Department of Education has taken an important step towards improving students’ and staffs’ health and wellbeing in our schools through providing CO2 monitors. The Government and educational establishments need to make the most of this opportunity and by implementing smart solutions, they have a chance to create safer learning environments which also provide long-term, cost-effective solutions for everyone.

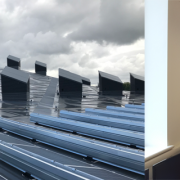

Most commonly used in classrooms the Hybrid Plus2 Aircool® is a quiet and energy-efficient hybrid ventilation system requiring minimal maintenance. It has different operational modes that are dependent on the internal and external environment. Sensors respond automatically to increases in temperature and CO2 and a boost function maximises fresh air supply. Suitable for a wall or window construction, the Hybrid Plus2 Aircool is lightweight and modular in design and can be ceiling-mounted or ducted within a ceiling void. The system is controlled by the Passivent iC8000 controller allowing for up to 40 individual zones to be managed.

Most commonly used in classrooms the Hybrid Plus2 Aircool® is a quiet and energy-efficient hybrid ventilation system requiring minimal maintenance. It has different operational modes that are dependent on the internal and external environment. Sensors respond automatically to increases in temperature and CO2 and a boost function maximises fresh air supply. Suitable for a wall or window construction, the Hybrid Plus2 Aircool is lightweight and modular in design and can be ceiling-mounted or ducted within a ceiling void. The system is controlled by the Passivent iC8000 controller allowing for up to 40 individual zones to be managed.